Hard ferrite (Ceramic)magnet is a non-metallic permanent magnetic material developed in the 1940s, composed of Fe2O3, BaO or SrO. Because its preparation process and appearance are very similar to ceramic products, it is sometimes called Ceramic magnet. Compared to metal magnets, Ferrite magnets have lower magnetic energy but are more resistant to demagnetization. Since Ferrite is mainly made of oxides, it is highly resistant to corrosion and oxidation. And can be made with both high and low coercive forces

Hard ferrite (Ceramic)magnet can be divided into two families based on their magnetic coercivity, their resistance to being demagnetized.Hard ferrites have high coercivity, hence they are difficult to demagnetize.They are used to make magnets, for devices such as refrigerator magnets, loudspeakers and small electric motors.Soft ferrites have low coercivity. They are used in the electronics industry to make ferrite cores for inductors and transformers,and in various microwave components.

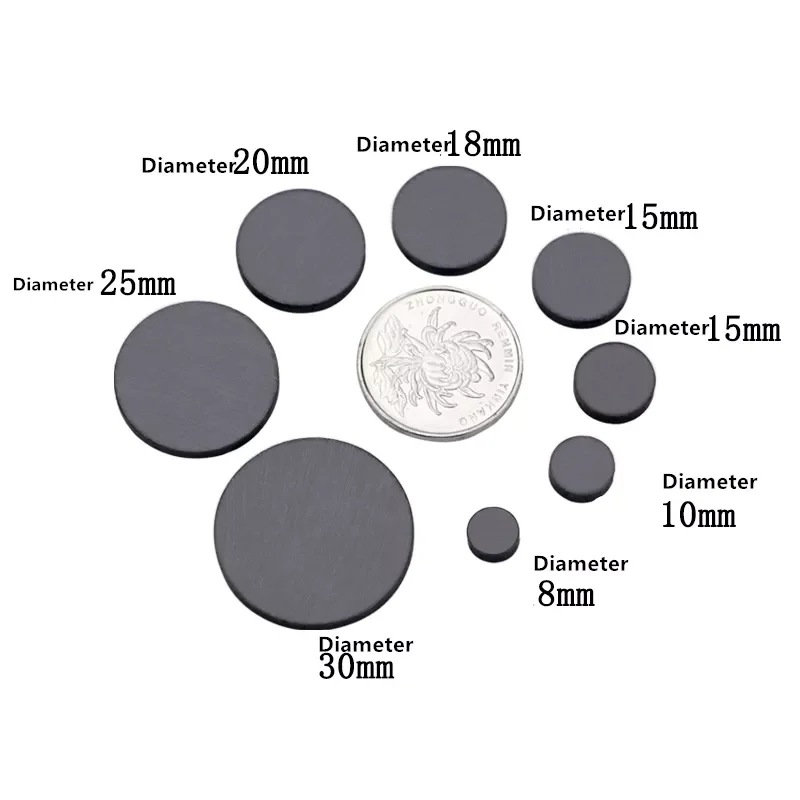

Hard ferrite (Ceramic)magnets shape: tile, cylinder, block, ring, bar, round, disc, special shape,etc,.

Hard ferrite (Ceramic) magnets application: motors, microwave appliance, louder speakers and earphone, medical apparatus, auto industry, machine gearings, sensors, meters and instruments, education field, magnetic holding systems.

PERFORMANCE OF FERRITE (CERAMIC) MAGNETS

Different markets use different naming standards. The “Y” nomenclature is the Chinese standard and is the most widely used. Contact us today to let us know what you are looking for, and we’ll help you find the solution for your project’s requirements.

Magnetic Properties

| Grade | Br | Hcb | Hcj | (BH)max | Tw | Equivalent | ||||

| mT | KG | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | °C | ||

| Y10T | 200~235 | 2.0~2.35 | 125~160 | 1.57~2.01 | 210~280 | 2.64~.52 | 6.5~9.5 | 0.8~1.2 | ≤250 | IEC~7/21 |

| Y20 | 320~380 | 3.2~3.8 | 135~190 | 1.70~2.38 | 140~195 | 1.76~2.45 | 18.0~22.0 | 2.3~2.8 | ≤250 | |

| Y22H | 310~360 | 3.1~3.6 | 220~250 | 2.77~3.14 | 280~320 | 3.52~4.02 | 20.0~24.0 | 2.5~3.0 | ≤250 | IEC~20/28 |

| Y23 | 320~370 | 3.2~3.0 | 170~190 | 2.14~2.38 | 190~230 | 2.39~2.89 | 20.0~25.5 | 2.5~3.2 | ≤250 | IEC~20/19 |

| Y25 | 360~400 | 3.6~4.0 | 135~170 | 1.70~2.14 | 140~200 | 1.76~2.51 | 22.5~28.0 | 2.8~3.5 | ≤250 | JIS~MPB320 |

| Y26H | 360~390 | 3.6~3.9 | 220~250 | 2.77~3.14 | 225~255 | 2.83~3.21 | 23.0~28.0 | 2.9~3.5 | ≤250 | TDK~FB3X |

| Y27H | 370~400 | 3.7~4.0 | 205~250 | 2.58~3.14 | 210~255 | 2.64~3.21 | 25.0~29.0 | 3.1~3.7 | ≤250 | IEC~25/22 |

| Y30 | 370~400 | 3.7~4.0 | 175~210 | 2.2~2.64 | 180~220 | 2.64~2.77 | 26.0~30.0 | 3.3~3.8 | ≤250 | IEC~26/18 |

| Y30BH | 380~390 | 3.8~3.9 | 223~235 | 2.80~2.95 | 231~245 | 2.90~3.08 | 27.0~30.0 | 3.4~3.7 | ≤250 | |

| Y30H-1 | 380~400 | 3.8~4.0 | 230~275 | 2.89~3.46 | 235~290 | 2.95~3.65 | 27.0~32.5 | 3.4~4.1 | ≤250 | TDK~FB4B |

| Y30H-2 | 395~415 | 3.95~4.15 | 275~300 | 3.46~3.77 | 310~335 | 3.90~4.21 | 28.5~32.5 | 3.5~4.0 | ≤250 | TDK~FB5H |

| Y32 | 400~420 | 4.0~4.2 | 160~190 | 2.01~2.38 | 165~195 | 2.07~2.45 | 30.0~33.5 | 3.8~4.2 | ≤250 | TDK~FB4A |

| Y33 | 410~430 | 4.1~4.3 | 220~250 | 2.77~3.14 | 225~255 | 2.83~3.21 | 31.5~35.0 | 4.0~4.4 | ≤250 | TDK~FB4X |

| Y35 | 400~410 | 4.00~4.10 | 175~195 | 2.20~2.45 | 180~200 | 2.26~2.51 | 30.0~32.0 | 3.8~4.0 | ≤250 | |