Samarium Cobalt (SmCo) magnets are high-performance permanent magnets with exceptional magnetic properties. They offer great temperature stability and high resistance to corrosion or demagnetization.

Samarium Cobalt is more resistant to corrosion than Neodymium magnets. As a result, they do not need any surface coating treatment to combat corrosion, Therefore are more suitable for demanding applications than Neodymium magnets.

SmCo magnets are ideal for industrial applications involving high or very low temperature, where magnetic stability is critical, space is a limited factor and high magnetic strength is required.

SmCo magnets operating temperatures are between 250 and 550 °C. Curie temperatures range from 700 to 800 °C.

A potential challenge is their propensity to chip and crack, due to their brittle nature. Therefore, they require careful handling and packing in order to prevent of damages to the magnets.

Sintering is the most common method used for manufacturing SmCo magnets, they can also be manufactured by injection molding and compression bonding.

Common applications for SmCo magnets: High performance permanent magnet motors, medical instruments, magnetic couplings, magnetic bearings, gyroscopes, accelerometers, voice coil motors, particle accelerators, sputtering deposition, magnetic separation devices, speakers, microphones, undulators, wigglers, particle beam focusing devices,and many others.

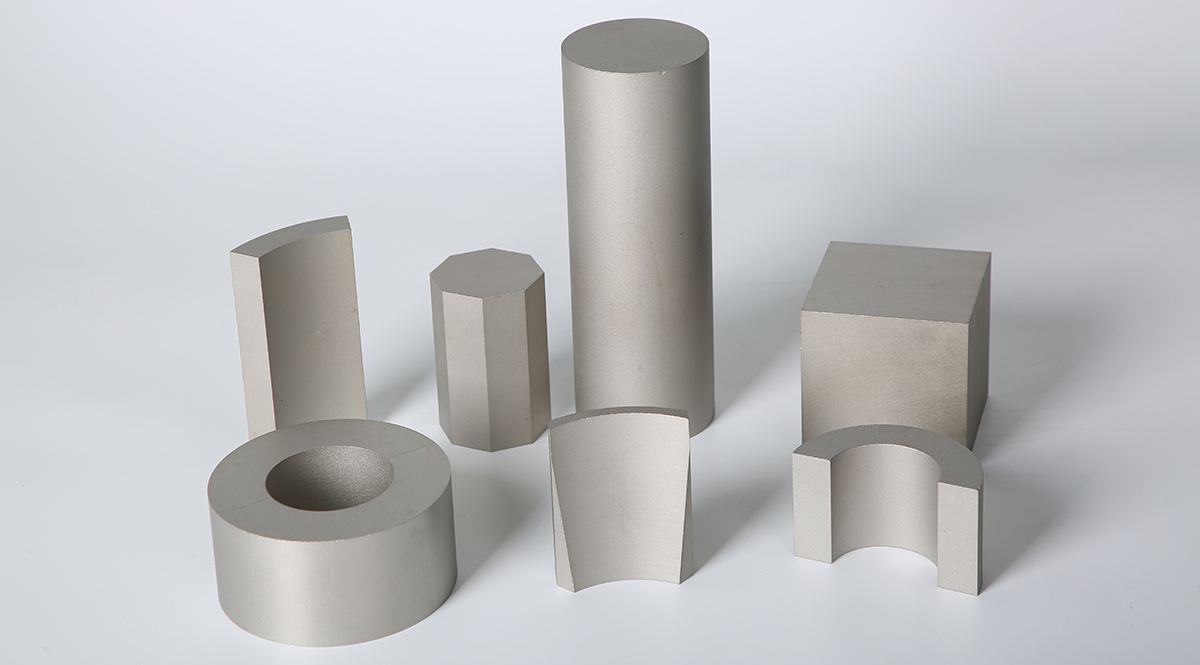

As a trust manufacturer of high-performance Samarium Cobalt (SmCo) magnets. We can custom fabricate specialty shapes and sizes to your exact specifications upon special request. Contact us today to let us know what you are looking for, and we’ll help you find the solution for your project’s requirements.

Physical Properties

| Density | Curie Temperature | Vickers Hardness | Compress Strength | Electrical Resistivity | Bend Strength | Tensile Strength | Thermal Expansion Coefficient | |

| g/cm3 | K | MPa | MPa | Ω·cm | MPa | MPa | 10-6/℃ | |

| SmCo (1:5) | 8.1-8.3 | 1000 | 450-500 | 1000 | 5-6×10-5 | 150-180 | 400 | //6 ⊥12 |

| SmCo (2:17) | 8.3-8.5 | 1100 | 550-600 | 800 | 8-9×10-5 | 130-150 | 350 | //8 ⊥11 |

Magnetic Properties

| Material | Grade | Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||

| kGs | mT | kA/m | kOe | kA/m | kOe | KJ/m3 | MGOe | °C | °C | ||

| SmCo(1:5) | SM-18 | 8.5 | 850 | 620 | 7.8 | ≥1350 | ≥17 | 145~150 | 17~19 | 750 | 250 |

| SM-20 | 9.0~9.6 | 900~960 | 653~717 | 8.2~9.0 | 1194~1513 | 15~19 | 150~175 | 19~22 | 750 | 250 | |

| SM-22 | 9.3~10.0 | 930~1000 | 660~772 | 8.3~9.7 | 1194~1751 | 15~22 | 159~191 | 20~24 | 750 | 250 | |

| SM-24 | 9.6~10.4 | 960~1040 | 660~780 | 8.3~9.8 | 1194~1751 | 15~22 | 175~207 | 22~26 | 750 | 250 | |

| SmCo(2:17) | SMG-24 | 9.5~10.2 | 950~1020 | 637~732 | 8.0~9.2 | 1433~1990 | 18~25 | 175~190 | 22~24 | 800 | 300 |

| SMG-26 | 10.2~10.5 | 1020~1050 | 748~796 | 9.4~10.0 | 1433~1990 | 18~25 | 195~215 | 24~26 | 800 | 300 | |

| SMG-28 | 10.5~10.8 | 1050~1080 | 756~796 | 9.5~10.0 | 1433~1831 | 18~23 | 205~220 | 26~28 | 800 | 300 | |

| SMG-30 | 10.7~11.2 | 1070~1120 | 677~820 | 8.5~10.3 | ≥1194 | ≥15 | 223~247 | 28~31 | 800 | 300 | |

| SMG-32 | 10.9~11.5 | 1090~1150 | 677~820 | 8.5~10.3 | ≥955 | ≥12 | 238~262 | 29~32 | 800 | 300 | |