Description

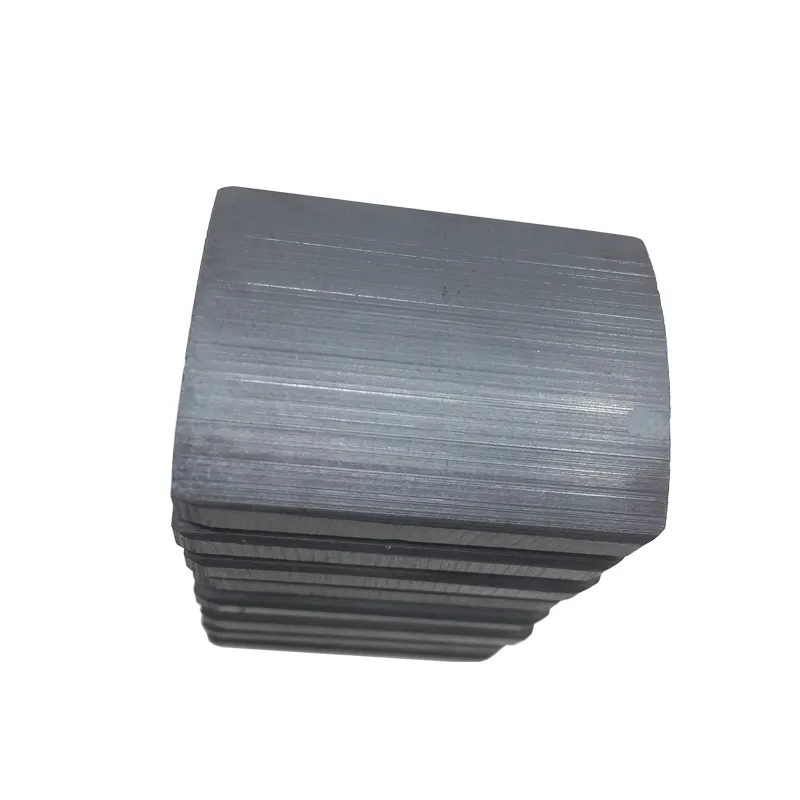

CERAMIC MAGNETS

Hard Ferrite Ceramic magnet is a permanent magnet mainly made of SrO or BaO and Fe2O3. Compared with other permanent magnets, ferrite magnets are hard, brittle and have low magnetic energy. However, it is not easy to demagnetize and corrode. The production process is simple and the price is low. Therefore, ferrite magnets have the highest output in the entire magnet industry and are widely used in industrial production.

Hard ferrite magnet is not mixed with metals such as nickel and diamond. It has high resistivity and large coercivity. It can be effectively used in large-gap magnetic circuits and is especially suitable as permanent magnets for small generators and motors.

| Product Name | Industrial Y40 Ferrite Magnets Arc Shape Ferrite Core Sintered Hard Ferrite Magnet Permanent Axial Arch Customized Magnet Size |

| Shape | Disc/Block/Arc/Ring/Bar/round or personalized request |

| Size | Customized as you need. Support OEM or ODM service |

| Density | 7.3-7.5 g/cm3 |

| Magnetism-Direction | Axial, Diameter, etc,. |

| Sample | Free sample for wholesale orders |

| Tolerance | 0.05mm-0.1mm |

| Max working Temperature | 80-200 Degrees Celsius |

| Certification | ISO9001:2008, ISO/TS16949:2009 and RoHS . |

| Packaging Details | Sea Pallet / Air Carton / Express Packaging / Plastic Tube |

| Delivery Time | 7-25 days |

| Application | Refrigerators, Speakers, and Small Electric Motors, DC motors, Magnetic Separators, Magnetic Resonance Imaging and Automotive Sensors. |

Ceramic Ferrite magnets characteristics

Mostly Used national standard – SJ285-77 permanent ferrite magnet standard

| Grade | Value(min/typical in our factory) | |||||||

| Br | Hcb(BHC) | Hcj(IHC) | (BH)max | |||||

| MT | KG | KA/m | Koe | KA/m | KOe | Kj/m^3 | MGOe | |

| Y10T(=C1) | 200/218 | 2.00/2.18 | 125/145 | 1.57/1.82 | 210/250 | 2.64/3.14 | 6.5/8.0 | 0.8/1.0 |

| Y25 | 360/370 | 3.60/3.70 | 135/150 | 1.70/1.88 | 140/170 | 1.76/2.14 | 22.5/25.3 | 2.8/3.2 |

| Y30(=C5) | 380/385 | 3.80/3.85 | 191/210 | 2.40/2.64 | 199/220 | 2.50/2.51 | 26.0/28 | 3.4/3.7 |

| Y30BH | 380/390 | 3.80/3.90 | 223/235 | 2.80/2.95 | 231/245 | 2.90/3.08 | 27.0/30.0 | 3.4/3.7 |

| Y33 | 410/420 | 4.10/4.20 | 220/235 | 2.77/2.95 | 225/240 | 2.83/3.01 | 31.5/33.0 | 4.0/4.2 |

| Y35 | 400/410 | 4.00/4.10 | 175/195 | 2.20/2.45 | 180/200 | 2.26/2.51 | 30.0/32.0 | 3.8/4.0 |

| C8(=C8A) | 385/390 | 3.85/3.90 | 235/255 | 2.95/3.20 | 242/265 | 3.05/3.33 | 27.8/30.0 | 3.5/3.7 |

| C10 | 400/410 | 4.00/4.10 | 288/300 | 3.62/3.77 | 280/287 | 3.51/3.60 | 30.4/31.9 | 3.8/4.0 |

Chinese SJ/T0410-2000 Permanent Ferrite Manget Standard

| Grade | BR | HcB | HcJ | (BH)max | ||||

| mT | KG | KA/m | Koe | KA/m | Koe | Kj/m | MGOe | |

| Y8T | 200~235 | 2.0~2.35 | 125~160 | 1.57~2.01 | 210~280 | 2.64~3.52 | 6.5~9.5 | 0.8~1.2 |

| Y20 | 320~380 | 3.2~3.8 | 135~190 | 1.70~2.38 | 140~195 | 1.76~2.45 | 18.0~22.0 | 2.3~2.8 |

| Y22H | 310~360 | 3.1~3.6 | 220~250 | 2.77~3.14 | 280~320 | 3.52~4.02 | 20.0~24.0 | 2.5~3.0 |

| Y23 | 320~370 | 3.2~3.7 | 170~190 | 2.14~2.38 | 190~230 | 2.39~2.89 | 20.0~25.5 | 2.5~3.2 |

| Y25 | 360~400 | 3.6~4.0 | 135~170 | 1.70~2.14 | 140~200 | 1.76~2.51 | 22.5~28.0 | 2.8~3.5 |

| Y26H | 360~390 | 3.6~3.9 | 220~250 | 2.77~3.14 | 225~255 | 2.83~3.21 | 23.0~28.0 | 2.9~3.5 |

| Y27H | 370~400 | 3.7~4.0 | 205~250 | 2.58~3.14 | 210~255 | 2.64~3.21 | 25.0~29.0 | 3.1~3.7 |

| Y28 | 370~400 | 3.7~4.0 | 175~2102 | 2.20~2.64 | 180~220 | 2.26~2.77 | 26.0~30.0 | 3.3~3.8 |

| Y30H-1 | 380~400 | 3.8~4.0 | 230~275 | 2.89~3.46 | 235~290 | 2.95~3.65 | 27.0~32.0 | 3.4~4.1 |

| Y30H-2 | 395~415 | 3.95~4.15 | 275~300 | 3.46~3.77 | 310~335 | 3.90~4.21 | 28.5~32.5 | 3.5~4.0 |

| Y32 | 400~420 | 4.0~4.2 | 160~190 | 2.01~2.38 | 165~195 | 2.07~2.45 | 30.0~33.5 | 3.8~4.2 |

| Y33 | 410~430 | 4.1~4.3 | 220~250 | 2.77~3.14 | 225~255 | 2.83~3.21 | 31.5~35.0 | 4.0~4.4 |

| Y35 | 430~450 | 4.3~4.5 | 215~239 | 2.70~3.00 | 217~241 | 2.73~3.03 | 33.1~33.2 | 4.16~4.17 |

In MMPA(0100-87) standard

| Grade | BR | HcB | HcJ | (BH)max | ||||

| mT | KG | KA/m | Koe | KA/m | Koe | Kj/m | MGOe | |

| C1 | 230 | 2.3 | 148 | 1.84 | 258 | 3.5 | 8.36 | 1.05 |

| C5 | 380 | 3.8 | 191 | 2.4 | 199 | 2.5 | 27 | 3.4 |

| C7 | 340 | 3.4 | 258 | 3.23 | 318 | 4 | 21.9 | 2.75 |

| C8A | 385 | 3.85 | 235 | 2.95 | 242 | 3.05 | 27.8 | 3.5 |

| C8B | 420 | 4.2 | 232 | 2.913 | 236 | 2.96 | 32.8 | 4.12 |

| C9 | 380 | 3.8 | 280 | 3.516 | 320 | 4.01 | 26.4 | 3.32 |

| C10 | 400 | 4 | 288 | 3.617 | 280 | 3.51 | 30.4 | 3.82 |

| C11 | 430 | 4.3 | 200 | 2.512 | 204 | 2.56 | 34.4 | |